- Feature:

-

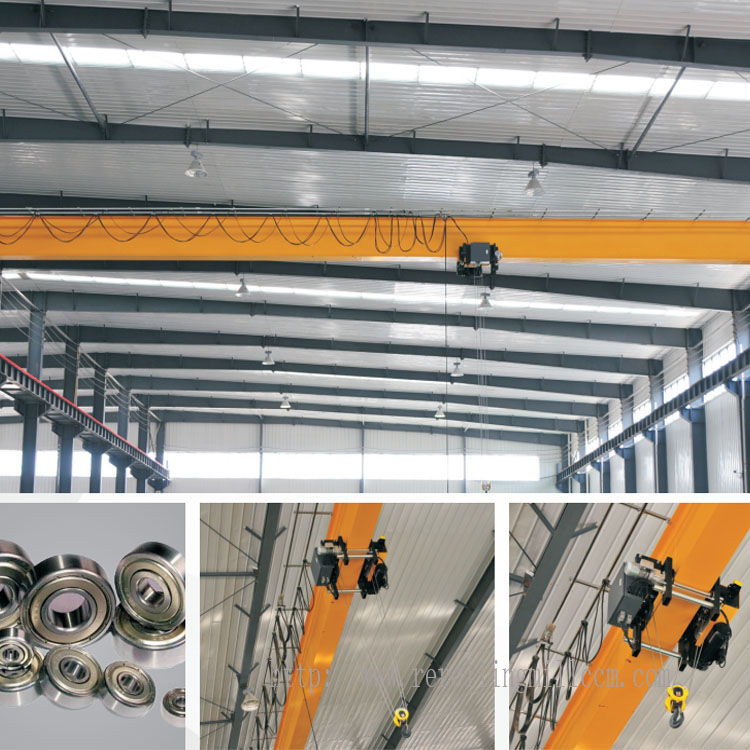

Bridge Crane

- Condition:

-

New

- Place of Origin:

-

Fujian, China

- Brand Name:

-

GEILI

- Certification:

-

ISO 9001:2015

- Application:

-

Industrial, Workshop Warehouse etc.

- Rated Loading Capacity:

-

5T - 30T

- Rated Lifting Moment:

-

100KN

- Max. Lifting Load:

-

50T

- Span:

-

21M, Customized

- Max. Lifting Height:

-

Customized

- Product Name:

-

Electric Lifting Machine Single Girder Overhead Crane

- Lifting Mechanism:

-

Eliectric

- Sling Type:

-

Wire Rope

- Working Temperature:

-

-25 ~ +40°C

- Crane Feature:

-

Energy-saving

- Type:

-

Single Girder

- Delivery Time:

-

30 Days

- After-sales Service Provided:

-

Engineers available to service machinery overseas

- Warranty:

-

1 Year

Product Description

Driver characteristics

1.Operation of large crane adopts traid frequency conversion driver,thus its operation is smooth and stable.

2.All aluminum housing of driver is small in volume, light in weight, and with good heat radiation performance.

3.Modularized design, direct driver installation, compact structure and high accuracy.

4.Unique electromagnetic design thus efficiently reduces electric current and extends service life.

5.Standard thermo sensitive switch, thus effectively uplifts safety grade.

6.Power input adopts heavy-load connector, thus the unloading is convenience and fast, safe and easy to operate.

Electric control system

1.Large crane electric control housing adopts standardized design, thus easy to replace and install.

2.Major electric element adopts international well-known brands such as Schneider and Simons etc.

3.Large crane limit standard equipment adopts Italian GG original importing brand, to ensure effectively safe operation and stop of crane.

4.Power supply of crane, big or small, adopts parallel installation of C type steel double track, enables little resistant and stable operation.

The characteristics of main frame of tail beam

1.The main body of tail beam adopts standard rectangular tube and numerical control automatic process.

2.Small space size stable structural properties, standardized connection with main beam, high interchangeability.

The characteristics of wheels

1.Its material selects to use high strength nodular cast iron, thus has good wearability and shock absorption capability.

2.Mondularized design, compact structure, high degree of standardization, easy to assembly parts.

3.DIN standard internal spline connection, automatic positioning, easy to install and dismantle.

Company Information

FUJIAN PUTIAN GEILI MACHINERY MANUFACTURING CO.,LTD

was founded in 1995,formerly known as Xianyou Rolling Mill Manufacturer.In 2001,merged with Xianyou Bangtou Mill Roll Manufacturer. In 2008,we focused on continuous casting and rolling production line equipment. In 2011,the company reorganized and established FUJIAN PUTIAN GEILI MACHINERY MANUFACTURING CO.,LTD ,which engaged in metallurgical equipment,mainly in steel-making,continuous casting and complete rolling production line research and development,design,manufacturing, installation and general contracting services.

Main products: all kinds of specifications continuous casting machines, rolling production line equipment and various auxiliary equipment, also the spare parts. Besides, we provide technical consultant, turnkey solution and one-stop service for steel plant of deformed rebar , wire rod , angle bar, channel beam, strip and other steel related production line. The Solution was based on the customer request, such as annual capacity from 30,000 tons to over 800,000 tons, rolling speed from 3 m/s to 90 m/s.

Our Service

1)Offering proposal with best solution and reasonable price for production line as per customers' invest and capacity requirement

2)Providing turn-key service of site planning, machinery designing, manufacturing, installation and commissioning for the full

production lines to meet customers requirement.

3)Technical support. We will arrange engineers on site to install and debug the production lines until the final products are meet to customers' require

4)Perfect after-sales with long-term technical support, such as after-sales adjust the production line, develop new products or improve the equipment

Quality Control:

Quality control (QC) is a procedure or set of procedures intended to ensure that a manufactured product or performed service adheres to a defined set of quality criteria or meets the requirements of the client or customer.

Finish Product QC

Ensure all the dimension and technical process are correct

Drawing QC

Ensure all the drawing are inspected by Profesional Enginners

Shipping QC

Ensure the product pass to customer are optimum and correct quantity.

Packing & Shipping

As a professional and experience manufacturer in China, we can supply designing, manufacturing, installation and commissioning of the equipment with "turn-key" service.

Please send us more information about your project, we would like to give you our proposal immediately after getting your details. Sincerely welcome you to come and visit our plant.

-

Steel Casting Machine High Quality Pouring Ladl...

View Detail -

Billet making continuous casting machine

View Detail -

Rolling Mill Manufacturer Electric CNC Continuo...

View Detail -

High Efficiency Industrial Electric Furnace for...

View Detail -

Continuous Casting Machine for Steel Slab Bille...

View Detail -

Metallurgy Equipment Rebar Cutters CNC Hydrauli...

View Detail