Bottom price Automatic Steel Pusher – Steel Plant Production Line from Steel Scrap to Billet, Billet to Final Product for Annual Output of TON -Geili Detail:

- Place of Origin:

-

Fujian, China

- Brand Name:

-

GEILI MACHINERY

- Model Number:

-

TR 8001

- Application:

-

Building Construction

- Diameter:

-

DIA 6mm - 50mm

- Length:

-

> 9m

- Standard:

-

AISI, ASTM, BS, GB, JIS

- Grade:

-

Carbon Steel

- Product name:

-

Deformed Steel Rebars

- Main Application:

-

Cnstruction Building

- Commodity:

-

Construction Deformed Steel Rebar

- Technique:

-

Hot Rolled Reinforced Steel Bar

- Material:

-

Steel

- Type:

-

Steel Rebar

- Shape:

-

Round, Square, Rectangle

- Certificate:

-

ISO 9001:2015

- Warranty:

-

1 Year

Steel Plant Production Line from Steel Scrap to Billet, Billet to Final Product for Annual Output of TON

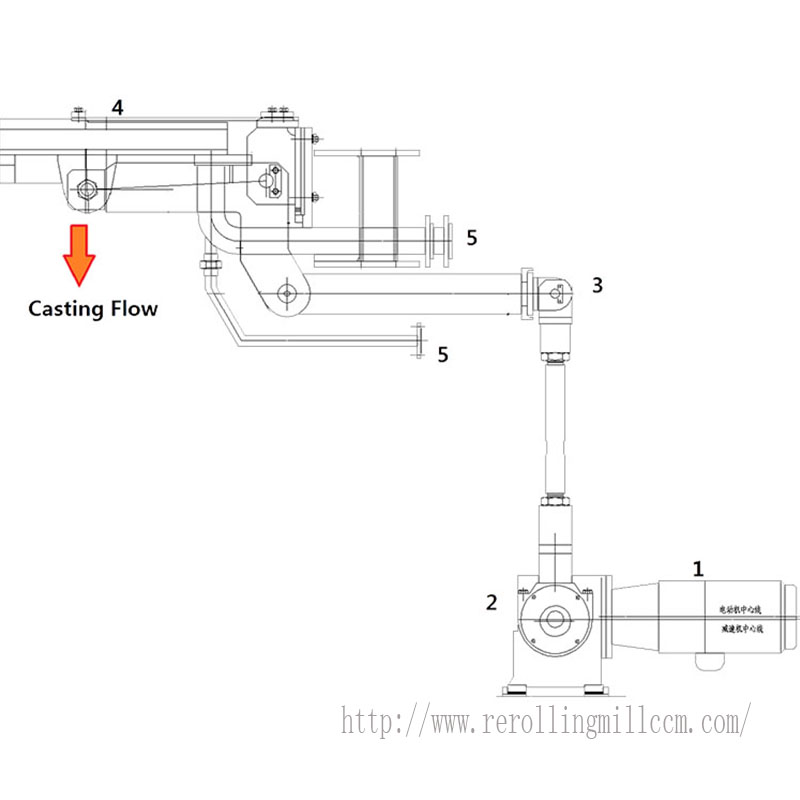

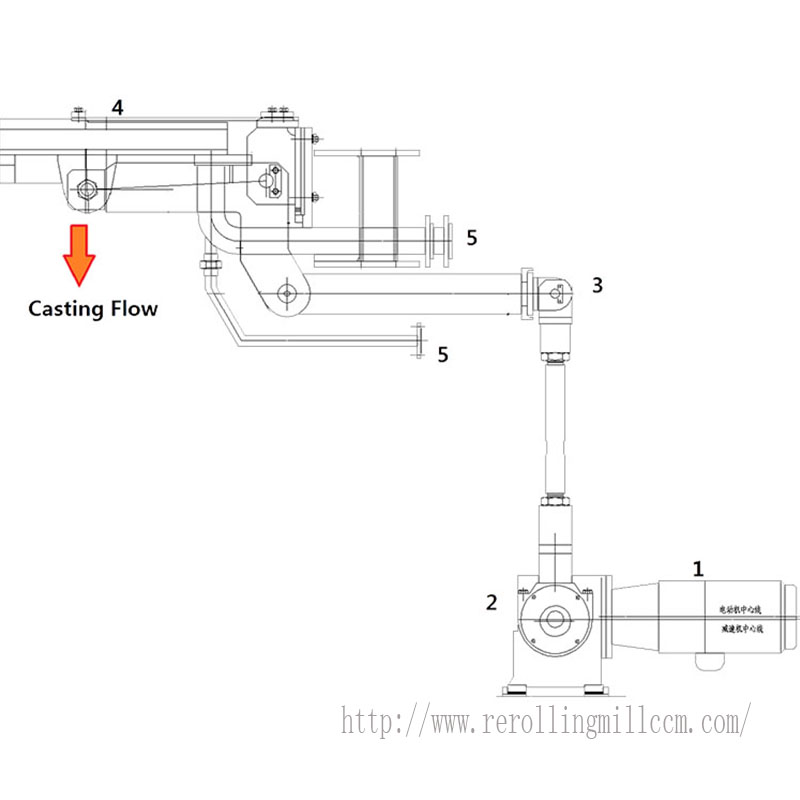

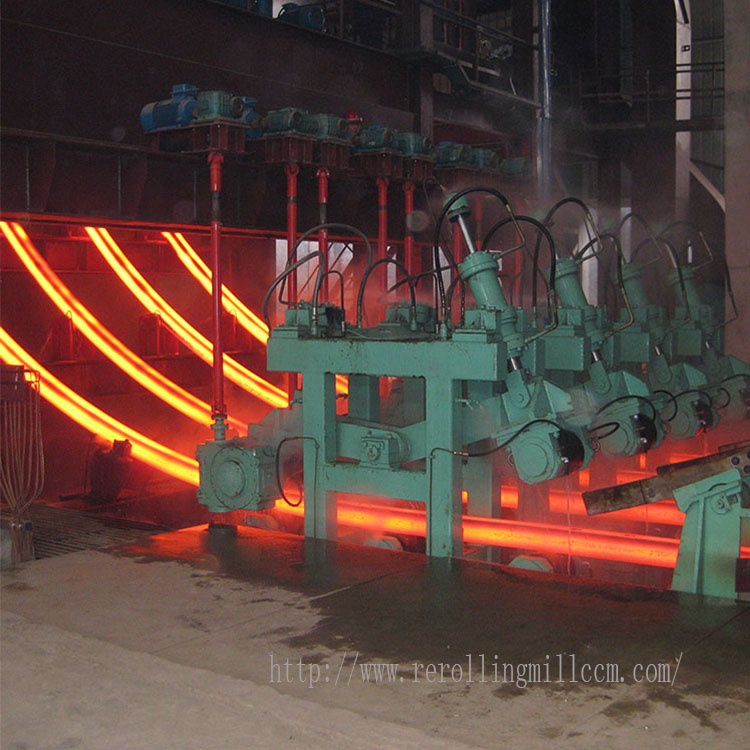

Continuous casting is a new energy-saving technique to casting the molten steel to a section shape or a certain size billet continuously and continuous casting machine is the equipment to complete this process. It includes pouring equipment, major equipment, cutting area equipment, dummy bar collection and transmission equipment. We supply the whole production lines, from induction furnace, CCM to rolling mills, cooling bed and packing.

Components:

· Turret charter

· Tundish

· Console frame of revolving operation box

· Tundish car

· Mould

· Recooling sprayer device

· Vibration device

· Dummy bar

· The storage device of dummy bar

· Cooling bed

· Water system

· Electronic control

· Flying shear

Technical Parameter:

Strand quantity: 1-10

Radius: R4-14M

Annual Output: 50,000 MT-180,000 MT/Strand

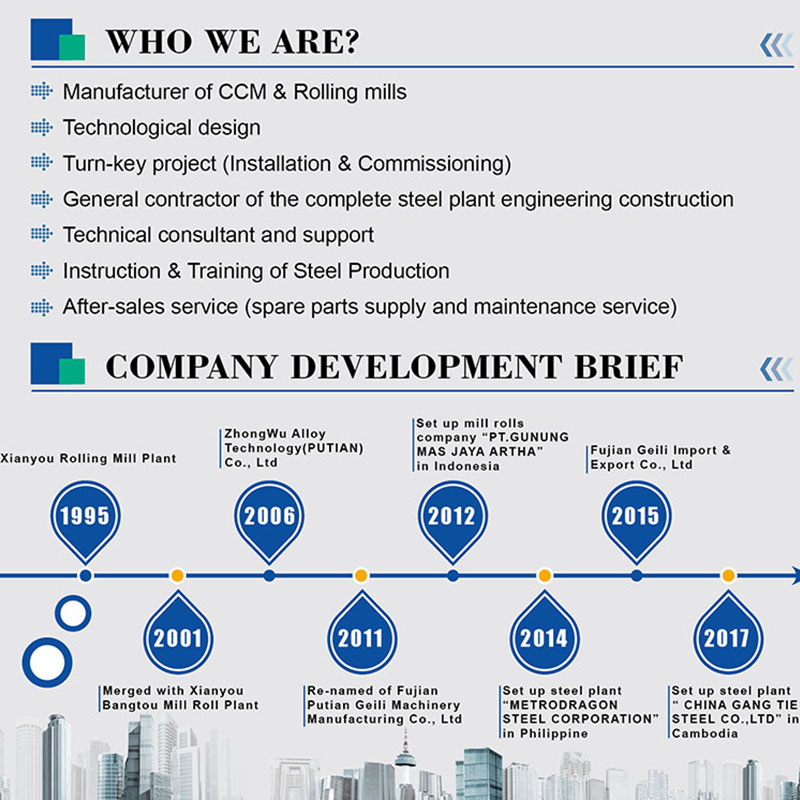

FUJIAN PUTIAN GEILI MACHINERY MANUFACTURING CO.,LTD

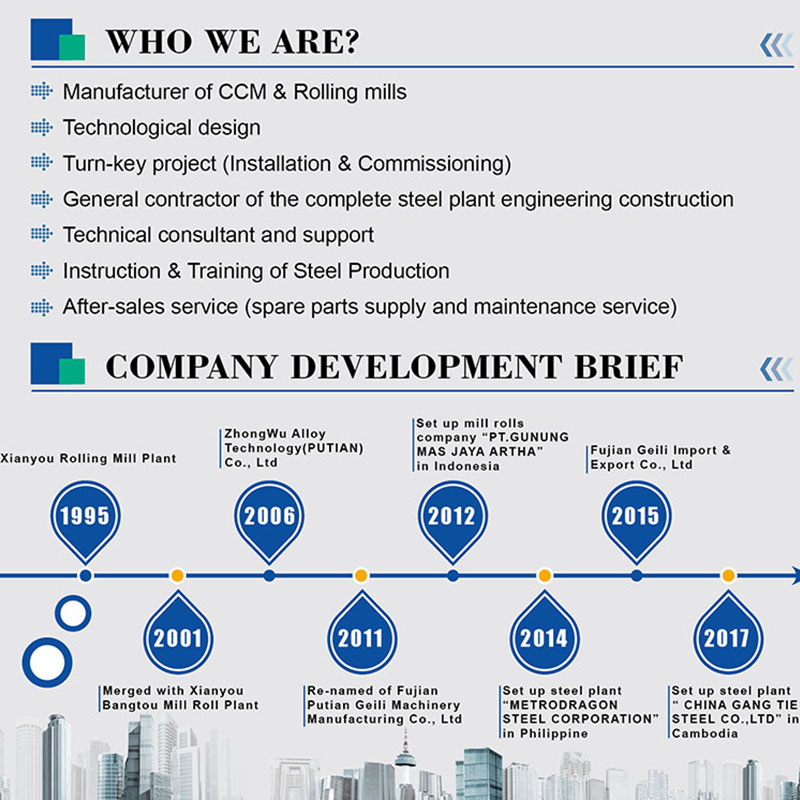

was founded in 1995,formerly known as Xianyou Rolling Mill Manufacturer.In 2001,merged with Xianyou Bangtou Mill Roll Manufacturer. In 2008,we focused on continuous casting and rolling production line equipment. In 2011,the company reorganized and established FUJIAN PUTIAN GEILI MACHINERY MANUFACTURING CO.,LTD ,which engaged in metallurgical equipment,mainly in steel-making,continuous casting and complete rolling production line research and development,design,manufacturing, installation and general contracting services.

1)Offering proposal with best solution and reasonable price for production line as per customers' invest and capacity requirement

2)Providing turn-key service of site planning, machinery designing, manufacturing, installation and commissioning for the full

production lines to meet customers requirement.

3)Technical support. We will arrange engineers on site to install and debug the production lines until the final products are meet to customers' require

4)Perfect after-sales with long-term technical support, such as after-sales adjust the production line, develop new products or improve the equipment

Quality Control:

Quality control (QC) is a procedure or set of procedures intended to ensure that a manufactured product or performed

service adheres to a defined set of quality criteria or meets the requirements of the client or customer.

Finish Product QC

Ensure all the dimension and technical process are correct

Drawing QC

Ensure all the drawing are inspected by Profesional Enginners

Shipping QC

Ensure the product pass to customer are optimum and correct quantity.

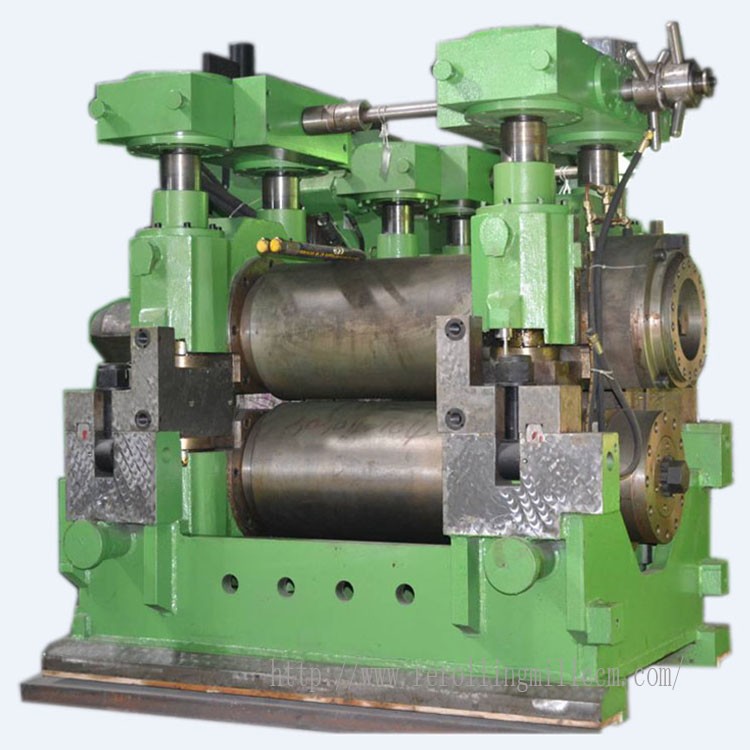

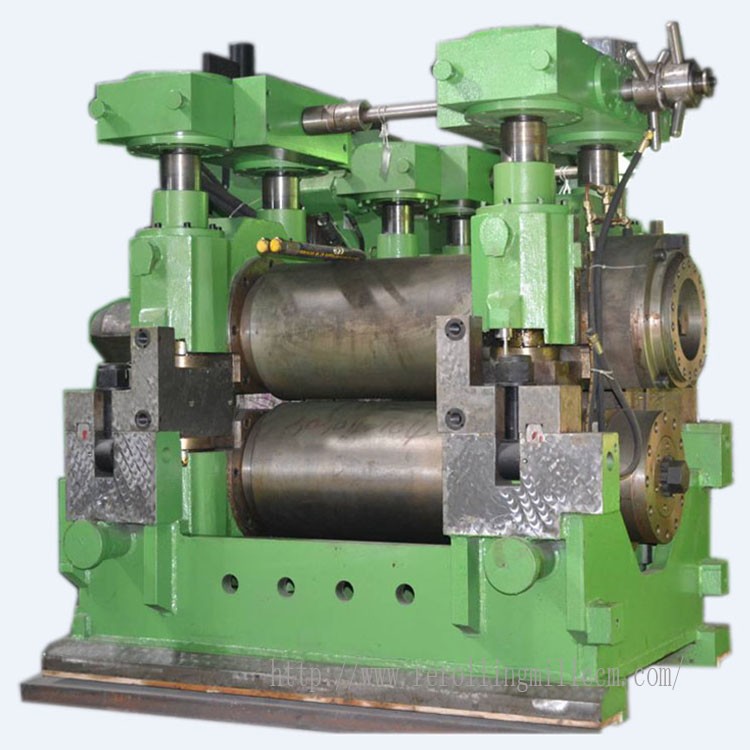

Product detail pictures:

Related Product Guide:

Cooperation

We constantly believe that one's character decides products' high quality, the details decides products' high-quality ,together with the REALISTIC,EFFICIENT AND INNOVATIVE crew spirit for Bottom price Automatic Steel Pusher – Steel Plant Production Line from Steel Scrap to Billet, Billet to Final Product for Annual Output of TON -Geili, The product will supply to all over the world, such as: Greece , Bahamas , luzern , We can meet the various needs of customers at home and abroad. We welcome new and old customers to come to consult & negotiate with us. Your satisfaction is our motivation! Let us work together to write a brilliant new chapter!

Factory equipment is advanced in the industry and the product is fine workmanship, moreover the price is very cheap, value for money!

-

Excellent quality Cluster Rolling Mill - Steel...

View Detail -

Factory wholesale Medium Frequency Induction Me...

View Detail -

Chinese wholesale Environmental Protection - C...

View Detail -

Factory Supply U-Beam – High Quality Hot ...

View Detail -

Factory Free sample Best Concast Machine - Fix...

View Detail -

Good Quality Flat Bar – China Factory Man...

View Detail