- Condition:

-

New

- Warranty:

-

1 Year

- Place of Origin:

-

Fujian, China

- Brand Name:

-

GEILI

- Usage:

-

Heat Treatment Furnace, Steel Melting

- Voltage:

-

380 V

- Certification:

-

ISO 9001:2015

- Type:

-

Induction Furnace, High Temperature Furnace

- Dimension(L*W*H):

-

Customized

- Product Name:

-

Heating Furnace

- Application:

-

Casting

- Capacity:

-

5-100t

- Function:

-

Power

- Advantage:

-

High Efficiency

- Feature:

-

Energy-saving

- Technology:

-

Advanced

- After-sales Service Provided:

-

Engineers available to service machinery overseas, Field installation, commissioning and training

- Power(W):

-

Customized

- Weight:

-

Customized

Product Description

Application

The production is a continuous working furnace,can complete the carburizing ,quenching and tempering heating treatment. Suitable for sheet carburizing , heating rods/bars/shafts/billets for foring and forming in forging production line.

Features

Heating is one of the most popular and best heating ways of metal material,has been widely used in fields applying oil,gas and coal heating,and is superior to oil,coal or other similar heating products by speedy heating,high efficiency and low production cost,low heating radiation,labor intensity and pollution conforming to environmental protection requipment,easily controllable temperature,small burning loss,high automatic degree that assures quality and enables production in semi-automatic and automatic machine tool and other advantages.

Advantage

work stable

safe protection

safe operation

small size

energy saving

rapid heating

| Description | Re-heating furnace |

| Brand | GEILI |

| Certificate | ISO, SGS |

| Technical | Please contact us |

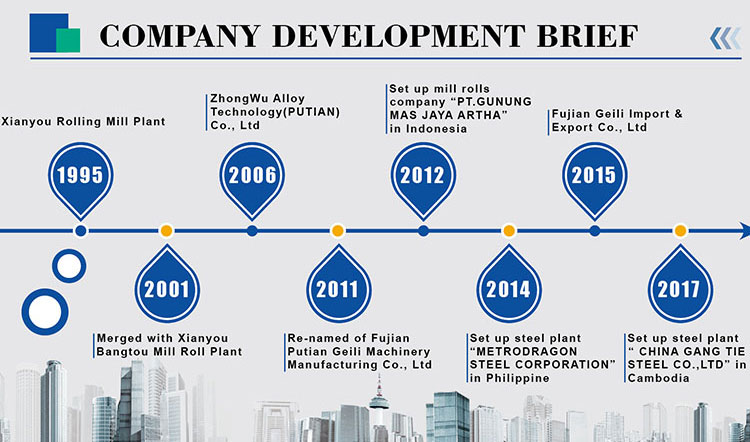

FUJIAN PUTIAN GEILI MACHINERY MANUFACTURING CO.,LTD

was founded in 1995,formerly known as Xianyou Rolling Mill Manufacturer.In 2001,merged with Xianyou Bangtou Mill Roll Manufacturer. In 2008,we focused on continuous casting and rolling production line equipment. In 2011,the company reorganized and established FUJIAN PUTIAN GEILI MACHINERY MANUFACTURING CO.,LTD ,which engaged in metallurgical equipment,mainly in steel-making,continuous casting and complete rolling production line research and development,design,manufacturing, installation and general contracting services.

Main products: all kinds of specifications continuous casting machines, rolling production line equipment and various auxiliary equipment, also the spare parts. Besides, we provide technical consultant, turnkey solution and one-stop service for steel plant of deformed rebar , wire rod , angle bar, channel beam, strip and other steel related production line. The Solution was based on the customer request, such as annual capacity from 30,000 tons to over 800,000 tons, rolling speed from 3 m/s to 90 m/s.

WHO WE ARE?

Manufacturer of CCM Rolling mills

Technological design

Turn-key project (Installation Commissioning)

General contractor of the complete steel plant engineering construction

Technical consultant and support

Instruction Training of Steel Production

After-sales service(spare parts supply and maintenance service

Pre-sales Service After-sales Service

Inquiry and consulting support. Training how to instal the machine, training how to use themachine

1) Providing professional proposal of suitable production line as per customers' invest and capacity requirement

2) Providing turn-key service of designing, manufacturing, installation and commissioning for the whole production lines to meet customers requirement

3) Providing foundation layout and arrangement diagram for your plant

4) Providing technical support. We will send various technical staff to the site until the final products are meet to customers' own request.

5) Good after-sales service will be provided. Our long-term technical service will be provided if you want to adjust the production line, develop new products or improve the equipment.

6) Quality warranty will be promised.

Quality Control:

Quality control (QC) is a procedure or set of procedures intended to ensure that a manufactured product or performed service adheres to a defined set of quality criteria or meets the requirements of the client or customer.

Finish Product QC

Ensure all the dimension and technical process are correct

Drawing QC

Ensure all the drawing are inspected by Profesional Enginners

Shipping QC

Ensure the product pass to customer are optimum and correct quantity.

Packing & Shipping

As a professional and experience manufacturer in China, we can supply designing, manufacturing, installation and commissioning of the equipment with "turn-key" service.

Please send us more information about your project, we would like to give you our proposal immediately after getting your details. Sincerely welcome you to come and visit our plant.

-

Electric Medium Frequency Induction Heating Fur...

View Detail -

High Temperature Heat Treatment Electric Heatin...

View Detail -

Low Energy Consumption Steel Melting Medium Fre...

View Detail -

Industrial ARC Furnace High Quality Steel Makin...

View Detail -

High Quality Industrial Furnace Energy Saving S...

View Detail -

Steel Reheating Furnace High Temperature Furnac...

View Detail