- Warranty:

-

1 Year

- Place of Origin:

-

Fujian, China

- Brand Name:

-

GEILI

- Condition:

-

New

- Dimension(L*W*H):

-

Customize

- Weight:

-

Customize

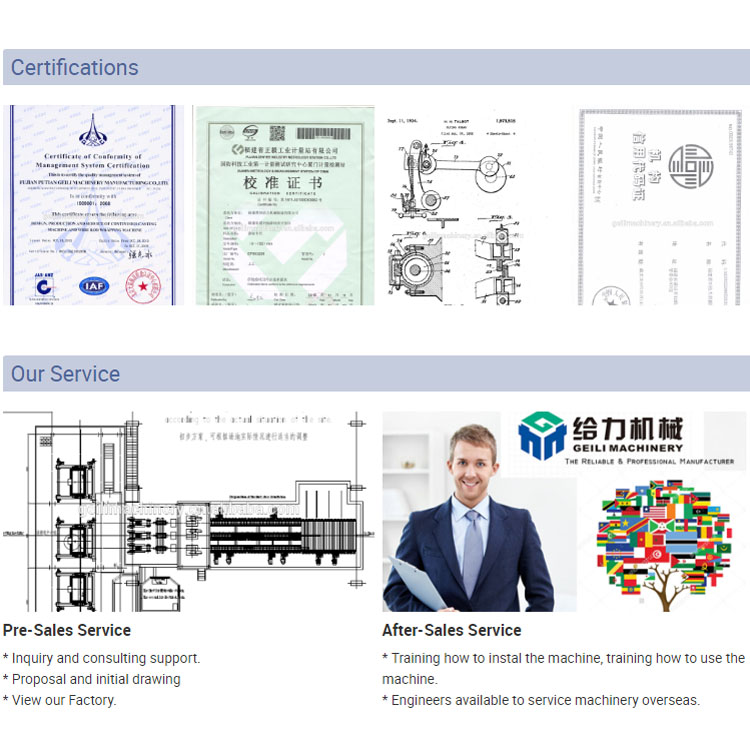

- Certification:

-

ISO 9001 2015

- Rated Power:

-

7.5KW - 38KW

- Voltage:

-

220V/380V

- After-sales Service Provided:

-

Overseas service center available, Field installation, commissioning and training

This shear is used to cut different sized metal tube and pipe materials.

Specification:

1.With hydraulic drive, convenient operation, simple maintenance.

2.Machine and Oil Tank was in set, without installation.

3.High pressure Cut, without breakout.

Maximum Shear: 70mmx70mm

The largest cut billet linear velocity: 3500mm/s

Advantage:

- Lower investment

- Steady performance

- Products are customized for different needs

- Production capability can be adjusted according to customer's request

- Low energy consumption

Features:

taking little space

lower noise

running stably

powerful cutting force

flexible operation and safety

Application:

Horizontal hydraulic shear are applied in recycling companies, automobile dismantling plants, smelting and casting industries to cold shear all shapes of profile steels and all kinds of metal into qualified furnace feed materials.

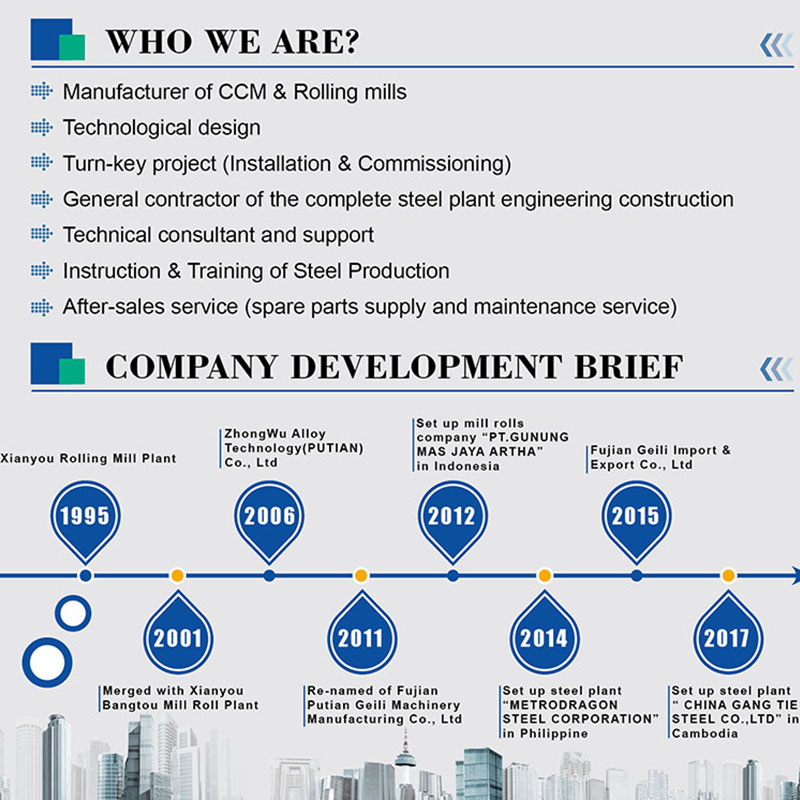

FUJIAN PUTIAN GEILI MACHINERY MANUFACTURING CO.,LTD

was founded in 1995,formerly known as Xianyou Rolling Mill Manufacturer.In 2001,merged with Xianyou Bangtou Mill Roll Manufacturer. In 2008,we focused on continuous casting and rolling production line equipment. In 2011,the company reorganized and established FUJIAN PUTIAN GEILI MACHINERY MANUFACTURING CO.,LTD ,which engaged in metallurgical equipment,mainly in steel-making,continuous casting and complete rolling production line research and development,design,manufacturing, installation and general contracting services.

Main products: all kinds of specifications continuous casting machines, rolling production line equipment and various auxiliary equipment, also the spare parts. Besides, we provide technical consultant, turnkey solution and one-stop service for steel plant of deformed rebar , wire rod , angle bar, channel beam, strip and other steel related production line. The Solution was based on the customer request, such as annual capacity from 30,000 tons to over 800,000 tons, rolling speed from 3 m/s to 90 m/s.

Q : Are you trading company or manufacturer?

A: We are manufacturer.

Q:How long is your delivery time?

A:Generally it is 60 days, it is according to quantity requires.

Q:What is the term of payment?

A: Payment <=1000USD, 100% in advance. Payment >=1000USD, 30% T/T in advance, balance before shipment.

Q:Do you have any Oversea Project?

A: Yes, we have service over 20 countries for their Plant set up Project.

If you are interested in this equipment, please don't hesitate to contact us!

If the machine is not suitable for your plant, please e-mail us the following information::

1. What’s the quality standard of billet do you want to casting? Is it common carbon steel or low carbon steel?

2. What’s the billet size and length?

3. Do you have melting furnace? If yes, how many tons of furnace with how many quantity?

4. What’s the capacity per hour?

According to your information, we will offer high efficiency design and best price for it.

-

High Efficiency Rolling Mill Machine for Steel ...

View Detail -

Steel Billet Continuous Casting Machine for Wir...

View Detail -

Swp265 Coupling Shaft/Cardan Shaft

View Detail -

High Quality Concast Machine for Continuous Cas...

View Detail -

Metal Metallurgy Machinery CNC Steel Shearing M...

View Detail -

Forming Machine / Hot Rolling Mill / Storage / ...

View Detail