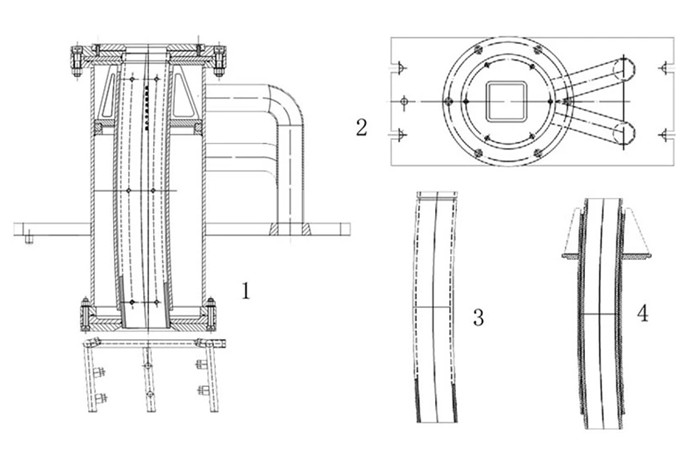

The mould is the key part of the Continuous Casting Machine. The mould quality will directly influence the quality and production of steel billets. The mould is for R4M to R10M with high quality, it is capable of producing square, round and rectangular billets.

The mould is the key equipment of a continuous caster for the satisfactory formation after cooling and preliminary casting of liquid steel and the smooth production

Adventage:

- Good quality

- Steady performance

- Products are customized for different needs

- ISO and SGS certificate The mould is for R4M to R10M with high quality, it is capable of producing square, round and rectangular billets.

The mould is the key equipment of a continuous caster for the satisfactory fromation after cooling and preliminary casting of liquid steel and the smooth production

Main characteristic:

| Cooling jacket | one-piece or stainless steel divided into segments |

| Water flow | 4 mm (may vary depending on different specifications of copper tubes of molds) |

| Hydraulic pressure | > 1.0 MPa |

| Coolant flow rate | 10-16 m/s |

-

Steel Rebar, Deformed Steel Bar, Iron Rods for ...

View Detail -

China Low Price Quartz Sand/ Refractory Silica ...

View Detail -

Deformed Reinforcing Steel Rebar B500b HRB500 I...

View Detail -

Hardness Alloy Guide/Mill Guide/Roller Guide

View Detail -

High Quality Ladle Furnace for Steel Melting of...

View Detail -

Ladle for Melting Steel High Quality Industrial...

View Detail