We're going to commit ourselves to giving our esteemed customers along with the most enthusiastically considerate providers for OEM Factory for China Auto Hanger Type Blast Cleaning Equipment with Casting Steel Shot for Auto Parts Shot Blasting, We focus on creating own brand and in combination with many experienced term and first-class equipment . Our goods you worth have.

We're going to commit ourselves to giving our esteemed customers along with the most enthusiastically considerate providers for China Blast Cleaning Equipment, Shot Blasting Machine, Further, we're supported by highly experienced and knowledgeable professionals, who have immense expertise in their respective domain. These professionals work in close coordination with each other to provide our clients an effective range of products.

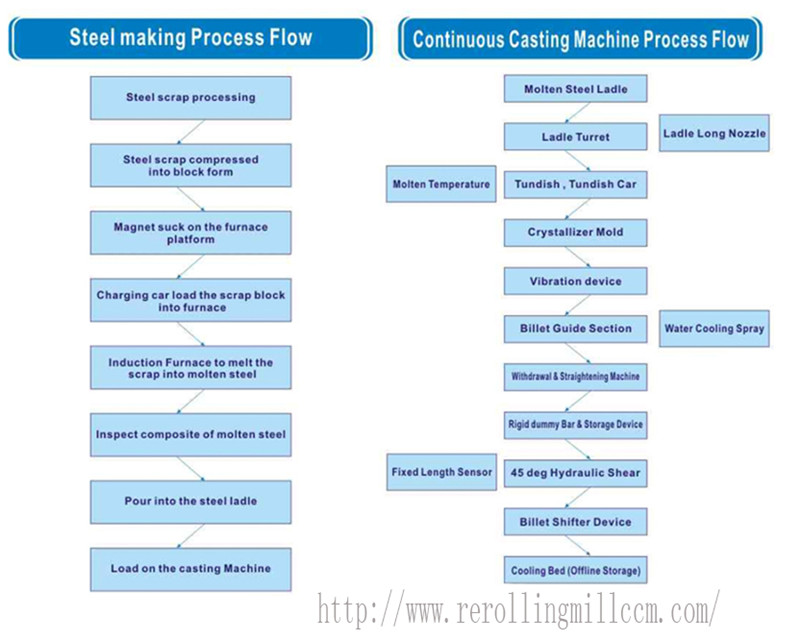

Continuous casting machine

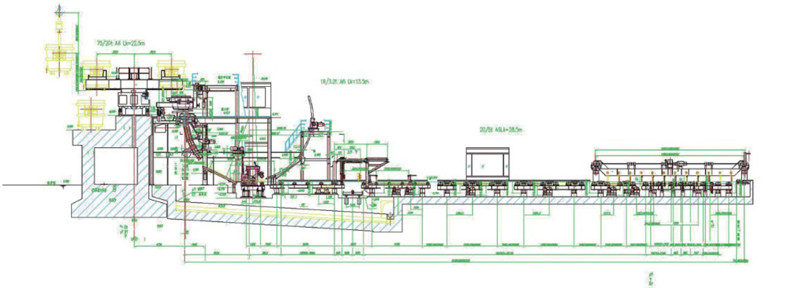

The continuous casting machines are including one-unit one-strand, two-unit two-strand, three-unit three-strand and multi-unit multi-strand. We are a company who can provide clients with integrative services from designing, manufacturing, installation to debugging of the continuous casting machine. We can also contract and manufacture the continuous casting machine according to clients' requirements.

Operation Principle:

Components:

- Turret charter

- Tundish

- Console frame of revolving operation box

- Tundish car

- Mould

- Recooling sprayer device

- Vibration device

- Dummy bar

- The storage device of dummy bar

- Cooling bed

- Water system

- Electronic control

- Flying shear

Technical Parameter:

| Casting radius | R3-14M |

| Billet specification | Round, square, rectangular |

| Strand quantity | According to output |

| Steel quality | Common carbon steel; Bearing steel; Low alloy steel and stainless steel, etc. |

| Cooling method | Fully water cooling |

1) Providing professional proposal of suitable production line as per customers' invest and capacity requirement

2) Providing turn-key service of designing, manufacturing, installation and commissioning for the whole production lines to meet customers requirement

3) Providing foundation layout and arrangement diagram for your plant

4) Providing technical support. We will send various technical staff to the site until the final products are meet to customers' own request.

5) Good after-sales service will be provided. Our long-term technical service will be provided if you want to adjust the production line, develop new products or improve the equipment.

6) Quality warranty will be promised.

Quality Control:

Quality control (QC) is a procedure or set of procedures intended to ensure that a manufactured product or performed service adheres to a defined set of quality criteria or meets the requirements of the client or customer.

Finish Product QC

Ensure all the dimension and technical process are correct

Drawing QC

Ensure all the drawing are inspected by Profesional Enginners

Shipping QC

Ensure the product pass to customer are optimum and correct quantity.

-

OEM Manufacturer China Hammer Crusher Wear Part...

View Detail -

New Arrival China China Equipment for Quenching...

View Detail -

Fast delivery China Intermediate Frequency Indu...

View Detail -

High Quality China Producing Cooling Bed Used f...

View Detail -

Excellent quality China CCM Steel Billets Conti...

View Detail -

Good Wholesale Vendors China Manganese Steel Pa...

View Detail