- Place of Origin:

-

Fujian, China

- Brand Name:

-

GEILI MACHINERY

- Model Number:

-

G508

- Certification:

-

ISO, GB, DIN, ASTM, EN

- Type:

-

Related parts

- Material:

-

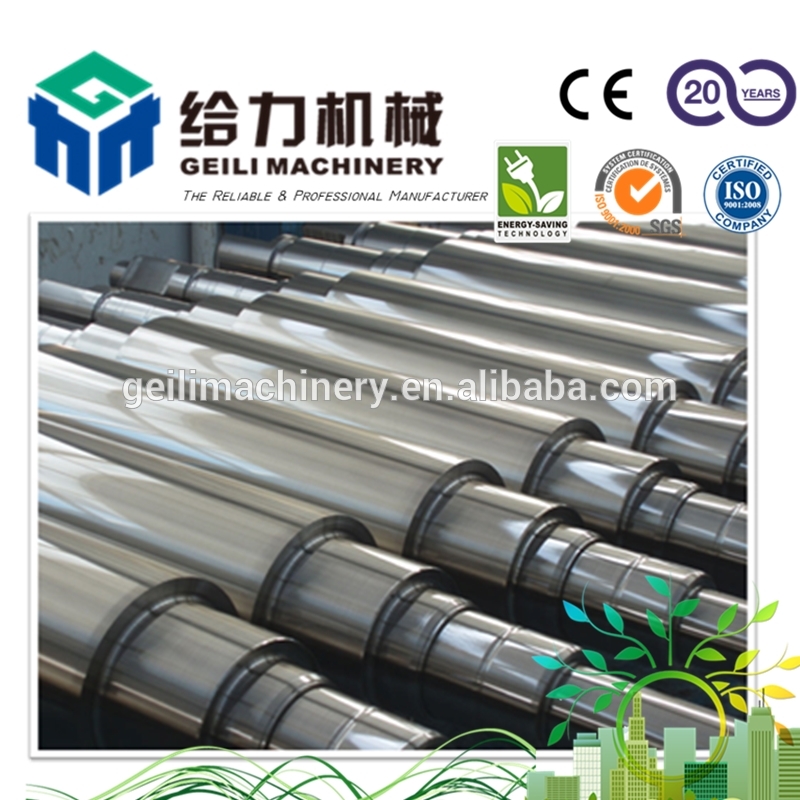

Alloy

- Plating:

-

Chrome

- Size:

-

Customised

- Usage:

-

Hot / Cold Rolling Mill

- Hardness:

-

HRC 55 - HRC 60

- Tensile Strenght:

-

400 Mpa - 1800 Mpa

- Surface Finish:

-

Powder Coated, Anti-Rust, .......

- Type Mill:

-

Intermediate Mill, Finishing Mill

- Features:

-

Chrome Material, Long life cycle, Anti-Rust

Fujian Geili Machinery Co., Ltd is a manufacturer specialized in research, development, manufacture and sales of continuous casting machine in China. Our company owns a group of high quality R & D team and professional & efficient management staff. Through implementation of full quality management, our company has passed ISO9000 , SGS , IAF quality system certification. Our company has hired experts with technical expertise to ensure the company to be at industrial leading position and technological frontier.

Pre-Sales Service

* Inquiry and consulting support.

* Planning layout and Design requires machinery

* Welcome visit our Factory.

After-Sales Service

* Engineers available to service machinery overseas.

* IN-TIME delivery goods.

* Free charges for installing, training and debugging.

* Long-term technical support.

Why Choose GEILI?

1. Expert R&D team and Professional service staff

2. Turn-Key service , Perfect after-sales service ,

3. OEM , Reliable Manufacturer

4. Competitive price , Optimum quality product

5. Machines easy operation, Steady performance, Low energy consumption

6. Lower investment , minimize maintenance

7. Products are customized for different requires

8. Adjustable production capability

9. On-time delivery

10. Warranty Period

Quality Control

Quality control (QC) is a procedure or set of procedures intended to ensure that a manufactured product or performed service adheres to a defined set of quality criteria or meets the requirements of the client or customer.

Finish Product QC

Ensure all the dimension and technical process are correct

Drawing QC

Ensure all the drawing are inspected by Profesional Enginners

Shipping QC

Ensure the product pass to customer are optimum and correct quantity.

Q : Are you trading company or manufacturer?

A: We are manufacturer.

Q:How long is your delivery time?

A:Generally it is 60 days, it is according to quantity requires.

Q:What is the term of payment?

A: Payment <=1000USD, 100% in advance. Payment >=1000USD, 30% T/T in advance, balance before shipment.

Q:Do you have any Oversea Project?

A: Yes, we have service over 20 countries for their Plant set up Project.

If you are interested in this equipment, please don't hesitate to contact us!

If the machine is not suitable for your plant, please e-mail us the following information::

1. What’s the quality standard of billet do you want to casting? Is it common carbon steel or low carbon steel?

2. What’s the billet size and length?

3. Do you have melting furnace? If yes, how many tons of furnace with how many quantity?

4. What’s the capacity per hour?

According to your information, we will offer high efficiency design and best price for it.

Straightening Machine

90.8% Response Rate

45 Deg Shearing Machine

87.4% Response Rate

Rolling Mill Machine

89.2% Response Rate

-

Customized Mill Rolls For Hot Rolling Mill

View Detail -

Casting Steel Roller High Speed Rolling Mill Ro...

View Detail -

High Efficiency Steel Rolls Mill Roll Industria...

View Detail -

Steel Rolling Mills ( Hot Roll ) Roll Forming M...

View Detail -

Rolling Mill Rolls High Speed Steel Embossing R...

View Detail -

Bainite Ductile Iron Roll ( SGA II ) For Hot Ro...

View Detail