- Condition:

-

New

- Warranty:

-

1 year

- After-sales Service Provided:

-

Field installation, commissioning and training, Field maintenance and repair service, Video technical support, Online support

- Place of Origin:

-

China

- Brand Name:

-

Geili

- Usage:

-

Melting Furnace

- Voltage:

-

380V-600V

- Type:

-

Arc Furnace

- Power(W):

-

100-5000KW

Product Description

The induction furnace is the device converting three phase power current into single phase intermediate frequency current and enabling metal to produce eddy current loss through electromagnetic field induction to achieve heating and melting and is applicable to melting, heating or holding of steel, copper, iron, aluminum, zinc, tin, nickel silver and other ferrous or nonferrous metal and alloy material as well as heating treatment prior to forging, sintering and tube-bending forming in casting and melting industries.

Performances and features

1) Using a zero-voltage scanning soft-start mode, in any case may at any time to start or stop, will not have impact on power supply.

2) Fast smelting with low production cost; low-pollution and environment-friendly;

3) A direct effect from the cold furnace melting. Dissolved material will be fully dumped clean. Molten material is easy to replace.

4) Power adjustment flexibility. Be able to continuously smooth adjustment. Temperature uniformity can be easily controlled. Oxidation burning is less.

5) Furnace shell using cast aluminum or steel structure, small footprint; furnace flip dump convenience, according to the need to use electric, manual, hydraulic tilting furnace and other means.

6) Designed to automatically adjust angle of inverter circuit that can automatically adjust the load impedance match, without adjustment of capacitance compensation and always run the equipment in good working condition; power supply system diagnostic error function, easy maintenance.

Furnace Usage

Melting Furnace Mainly used in melting steel, iron, copper, aluminum and alloy, is with high melting efficiency, good electricity saving effect, good metal component uniformity, less burning loss, speedy temperature rise, easy control of temperature, is suitable to all kinds of metal melting.

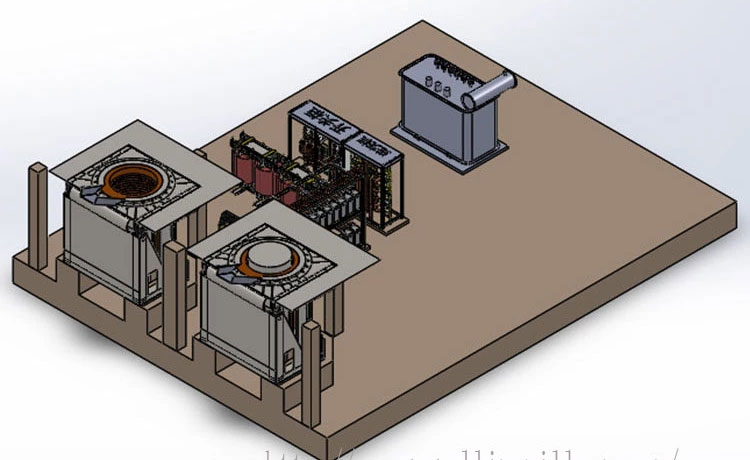

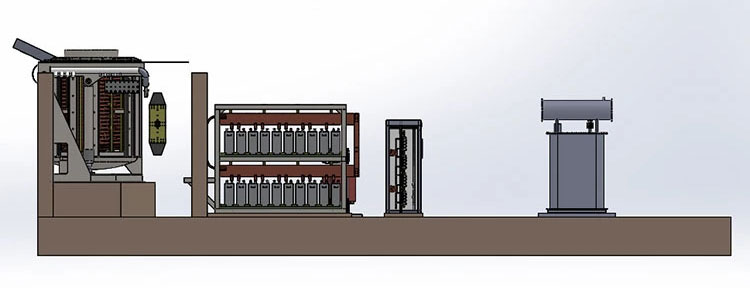

Smelting Furnace constitution

1. Furnace body

2. Medium frequency power supply cabinet

3. Water cooling cable

4. Reduction machine

5. Crucible mold

6. Compensation capacitor rack.

7. Chiller

8.Transformer

9. Installation drawings and specifications

-

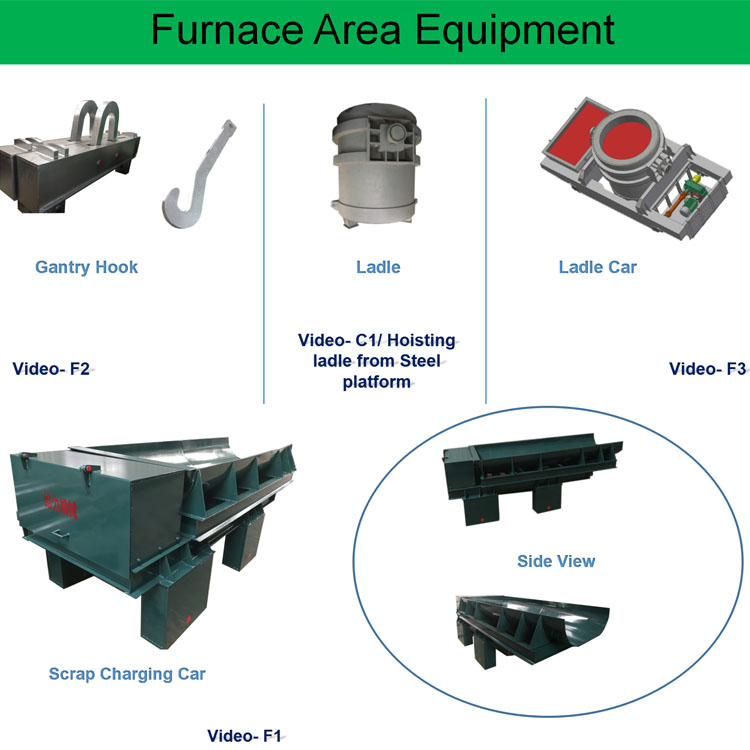

Molten steel ladle car

View Detail -

Industrial Electric Steel Melting Induction Fur...

View Detail -

Medium Frequency Furnace High Efficiency Heatin...

View Detail -

Electric High Temperature Furnace for Industria...

View Detail -

Electric Medium Frequency Induction Heating Fur...

View Detail -

High Efficiency Natural Gas-Furnace Oil R-heati...

View Detail