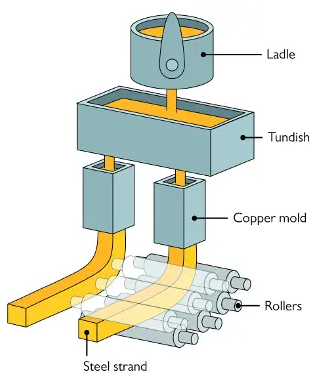

To transfer liquid steel from a teeming ladle to the continuous casting machine mould, an intermediate vessel, called a tundish, is used.

Main components:

Supporting structure

Tilting frame

Gas burner

Combustion air fan

Hydraulic cylinder

Hydraulic power unit

Electrical control panel

Features:

a) Distribution of hot steel from ladle into the individual strand

b) Separation of remaining inclusions

c) Optimized shape of the tundish to have got optimal steel flow into moulds

d) Controlled temperature drop of the liquid steel

e) Triangle shape of the tundish to prevent the refractory lining apart from the tundish for distortion

-

Investment Casting CCM Plant for Steel Continuo...

View Detail -

China Origin Mill Price Direct Hot Rolled Steel...

View Detail -

Cutting Tools/Rolling Tools/Cutting Blade

View Detail -

Galvanised Steel C Channel and U Channel Sections

View Detail -

Hot Selling Galvanized U Channel Price

View Detail -

Hot Rolled Mild Steel Q235B I Beam

View Detail