- Condition:

-

New

- Warranty:

-

1 Year

- Place of Origin:

-

Fujian, China

- Brand Name:

-

GEILI

- Voltage:

-

380 V

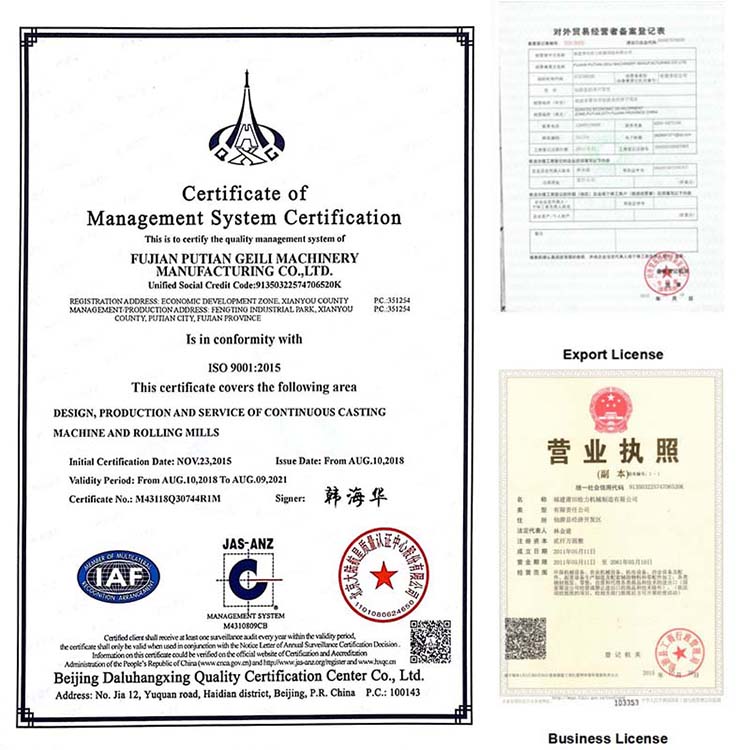

- Certification:

-

ISO 9001:2015

- Application:

-

Bar

- Weight:

-

100 Tons

- Production Capacity:

-

98%

- Dimension(L*W*H):

-

R5.25

- Power(W):

-

1500 KW

- Applicable Industries:

-

Manufacturing Plant

- Casting Type:

-

Round, Square, Rectangle

- Steel Type:

-

Carbon Steel, Bearing Steel, Low Alloy

- Product name:

-

Steel Rebar Rolling Plant Continuous Casting Investment

- Color:

-

Customized

- Material:

-

Steel

- Feature:

-

High Efficiency

- Technology:

-

Advanced

- Price:

-

Normal

- Function:

-

Casting Steel

- Delivery Time:

-

60 Days

- After-sales Service Provided:

-

Field installation, commissioning and training

Production Description

Continuous casting is a new energy-saving technique to casting the molten steel to a section shape or a certain size billet continuously and continuous casting machine is the equipment to complete this process. It includes pouring equipment, major equipment, cutting area equipment, dummy bar collection and transmission equipment. We supply the whole production lines, from induction furnace, CCM to rolling mills, cooling bed and packing.

Company Information

|

Customer Requirement |

Capacity, electricity, land, etc. |

|

Solution Discussion |

Technical and design discussion; Most suitable proposal. |

|

Initial Stage |

Provide plan layout diagram; Provide quotation machinery list. |

|

Detail Check & Confirm |

On-site inspection & verification; Both parties more details discussion. |

|

Contract Confirmation |

Final price, supply scope, terms & conditions etc. |

|

Payment |

Pay advance payment into the sellers's account; Issue original irrevovable L/C. |

|

Equipment Production |

Design and manufacture according to the supply list and equipment parameters in the contract. |

|

Shipping Transportation |

Delivery at the appointed time; Provide equipment shipping list and customer declaration data. |

|

Site Construction |

Equipment foundation; Supervision for the complete plant engineering; Installation. |

|

Equipment Commissioning |

Conduct cold commissioning and hot commissioning after installation. |

|

Final Acceptance |

Buyer's final acceptance of equipment; Training provided by the supplier. |

| Perfect Service |

24-hour after-sales service; Provide spare parts purchasing and matainance service technical support. |

Quality Control:

Quality control (QC) is a procedure or set of procedures intended to ensure that a manufactured product or performed service adheres to a defined set of quality criteria or meets the requirements of the client or customer.

Finish Product QC

Ensure all the dimension and technical process are correct

Drawing QC

Ensure all the drawing are inspected by Profesional Enginners

Shipping QC

Ensure the product pass to customer are optimum and correct quantity.

FAQ

Q : Are you trading company or manufacturer?

A: We are manufacturer.

Q:How long is your delivery time?

A:Generally it is 60 days, it is according to quantity requires.

Q:What is the term of payment?

A: Payment <=1000USD, 100% in advance. Payment >=1000USD, 30% T/T in advance, balance before shipment.

Q:Do you have any Oversea Project?

A: Yes, we have service over 20 countries for their Plant set up Project.

If you are interested in this equipment, please don't hesitate to contact us!

If the machine is not suitable for your plant, please e-mail us the following information::

1. What's the quality standard of billet do you want to casting? Is it common carbon steel or low carbon steel?

2. What's the billet size and length?

3. Do you have melting furnace? If yes, how many tons of furnace with how many quantity?

4. What's the capacity per hour?

According to your information, we will offer high efficiency design and best price for it.